IoT’s Impact on the Food Industry: Exploring its Role, Benefits, and Challenges

The Internet of Things (IoT) has made its way into different industries like transportation, finance, agriculture, hospitality, and manufacturing. However, the food and beverage (F&B) sector is lagging behind in adopting IoT and the latest technologies into its operations. In this article, you’ll find out what the food industry can gain from the Internet of Things.

IoT’s contribution to the food industry

The F&B sector, especially food service businesses, can significantly benefit from IoT because of its potential to add real value and improve effectiveness in businesses involved in the distribution, delivery, and selling of food and beverages.

According to a report by ReportLinker:

“The Internet of Things (IoT) and traceability for food and beverage (F&B) manufacturing market was valued at $4.08 billion in market revenue in 2017 and is expected to reach $8.43 billion by 2025, growing at a compound annual growth rate (CAGR) of 9.5%”.

If the Food and Beverage Industry integrates IoT effectively into its operations, it can reach its highest potential. It can help F&B businesses enhance food safety, reduce waste, and improve traceability. Overall, F&B businesses that use IoT can significantly reduce costs and risks involved in different levels of their business model, including food processing and packaging.

In the Food and Beverage Industry, it is essential to provide customers with high-quality food and improve their overall experience. To achieve this, food quality must be controlled, even during storage, before it is acquired by consumers.

Proper storage involves maintaining the right temperature and humidity levels in storage facilities, particularly for perishable goods like meat and dairy. To achieve this efficiently, equipment and facilities in stores and warehouses must be monitored 24/7, even when employees are not on-site or when the locations are closed.

When food is not properly stored, its quality will suffer, and in the worst cases, it may rot and become inedible, thus causing unwanted expenses and loss of inventory.

How can IoT benefit the food industry?

There are so many benefits of adopting IoT in the food industry. In fact, the use of technology within the industry has shown great promise in the last few years, including the following.

1. Supply chains with greater transparency

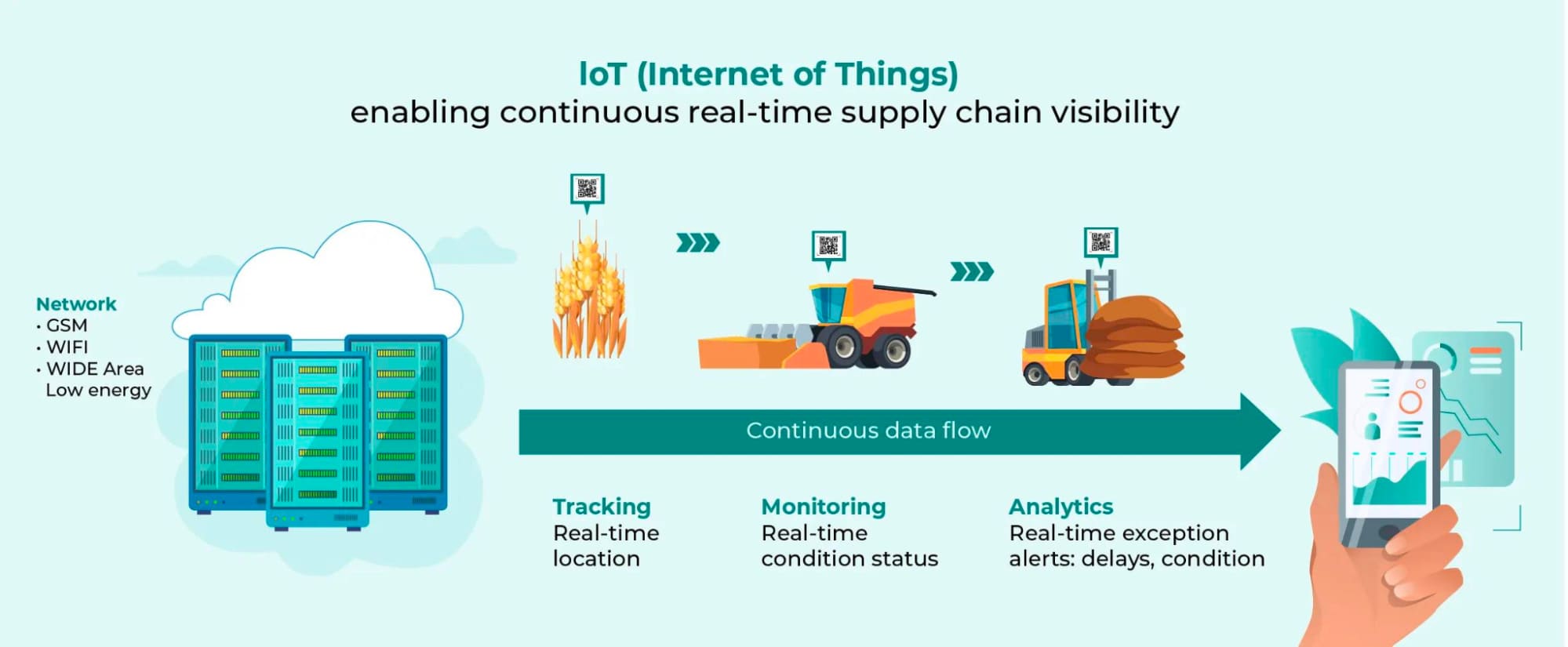

Traceability and transparency have proved to increase consumers’ trust and loyalty to businesses since the global supply chain has made them one of its priorities. This change in the global supply chain’s handling of products allows both consumers and businesses to see where their products have gone through from farm to store. With IoT, this process can become easier and more practical.

Real-time supply chain visibility. Source: Cropin

Imagine a customer going to his/her local store to pick up a bag of potato chips. With IoT technology, he/she can access all the information about all the available brands of potato chips in the store within seconds by scanning QR codes. The customer can identify the origin of the products, the ingredients used, the production date, the expiry, what packaging was used, and how it reached the store.

All this information can be used by the customer to make a decision about which brand of potato chips to buy. In addition, businesses can gain more of their customers’ trust by providing all this information.

2. Enhanced food safety

The Food and Drug Administration of the United States (FDA), the global leader in food safety and the principal organization in the evolution of the food industry, implemented the Food Safety Modernization Act (FSMA) in 2011. This law aims to transform the organization’s approach to combating foodborne illnesses, from being reactive to food contamination cases to becoming more proactive and improving food safety through preventive methods.

FSMA prompted the F&B industry to prioritize food safety even more. It has also allowed F&B businesses to see the importance of IoT in providing their customers with high-grade products while following FSMA guidelines.

- • Monitoring sensors are used to maintain the quality of food products by regulating temperature, humidity, and shipping time, among other factors, to ensure that food is stored in an environment with the ideal food storage conditions.

- • Real-time sensors that monitor temperature are used to ensure food safety during the delivery, processing, storage, or store display of temperature-sensitive food products.

- • Staff will be able to immediately identify food safety violations and potential issues and perform mandatory inspections right away.

- • Packaging businesses and food processing industries now put sensors in their food packaging to increase traceability within the supply chain and make tracing and tracking of products much easier.

3. Optimized logistics

Warehouse logistics. Source: Unsplash

Just like in other industries, F&B can also benefit from using IoT in its logistics operations. IoT can be used to make real-time tracking of products easier and assist in automating shipments through replenishment forecasting.

One way to achieve this is through the use of Radio-frequency Identification (RFID) transmitters and GPS systems that can make monitoring easier throughout the distribution chain.

With this type of system in place, businesses in the F&B industry can gather more customer data, enabling them to identify their customers’ needs with greater accuracy and thereby reducing waste. RFID technology is also useful in providing the food supply chain with real-time information about their products, enabling the automation of deliveries and better control of storage conditions during shipping.

Moreover, it can provide businesses with accurate reports on their products’ performance in specific locations. This information can help businesses identify consumer behavior and optimize their delivery vehicles for maximum efficiency.

4. Increased operational efficiency

Typical vending machines. Source: Unsplash

Reduced manual processes, smoother workflows, lower costs, and less waste result in higher operational efficiency in the Food and Beverage industry. These are the goals that most businesses in the food sector are striving for in order to accelerate growth and increase profits.

A good example of this is the growth of the vending machine industry, which has increased by 3 percent from 2018 to 2022 according to Business Wire. This growth is attributed to the introduction of cashless payment technology in the design of new smart vending machines.

The use of IoT in the vending machine industry has enabled retail processes to become more automated, thereby reducing operational costs. In addition, smart vending machines can provide businesses with valuable customer insights, product traceability, real-time monitoring of food and beverage quality, and replenishment forecasts.

5. Energy savings

Tracking energy usage and spending can be a challenging task, particularly for restaurant owners who use multiple appliances to run their kitchens. This task can be even more difficult for those who use older appliance models that tend to consume more electricity. Moreover, older appliances are more prone to unwanted and unexpected malfunctions, which can disrupt maintenance schedules.

To address this issue, Energy Management Solutions (EMS) technology has been developed to manage the power consumption of food companies. This technology is currently being used by restaurant owners who have adopted IoT.

American West Restaurant Group said:

“Pizza hut expects an 18% reduction in average monthly energy usage and saves $2 million in energy costs between 2018 to 2022, all because of IoT,”

For example, restaurants can now use smart appliances to reduce their energy consumption. There are smart appliances available that can maintain set temperatures and notify cooks when the food is ready, such as smart fryers. In addition, these appliances can inform cooks when the oil needs changing or filtering to improve the quality of the food. This technology can help restaurants save on energy costs and reduce waste, such as the untimely disposal of oil.

Smart fridges are also becoming a popular option for restaurants due to their data collection capabilities. Some smart fridges can even be integrated with the Point of Sale (POS) system and used for real-time analytics and data gathering. This technology can assist restaurant staff in identifying which items in their inventory need replenishing and how many items the fridge can hold to avoid an excessive thermal transfer.

6. Reduce waste

Food wastage. Source: Unsplash

IoT technology not only helps businesses become more profitable, but it can also benefit the environment by reducing food waste.

Every year around 40 percent of food goes to waste before even reaching consumers, according to the National Resource Defence Council.

This waste can be reduced by using IoT in food processing, such as attaching sensors to pallets used for carrying new harvests. These sensors can monitor factors like time and temperature, which can help identify the period before certain products begin to rot.

Then, when the newly harvested produce arrives at the storage facilities or their next destination, workers can determine whether they will need additional moisture or lower temperatures, depending on the information that the sensors provide.

Internet of Things food manufacturing systems, such as those that handle food and water waste, can help the food industry reduce expenses and waste by providing essential data across the food supply chain.

Challenges in the F&B Industry and IoT Solutions

The food and beverage industry faces many challenges that can cause businesses to lose money, time, and resources. These challenges include:

1. Data sorting challenges

Manual sorting of data in the F&B industry is a challenging task to accomplish. Moreover, it is time-consuming and prone to human error.

Solution: With IoT in the food and beverage industry, data gathering is faster and easier since data is collected in real-time through computers, sensors, cameras, and software that are integrated into appliances/machines.

2. Shortage of personnel

The traditional food manufacturing industry heavily depends on human resources, but it is currently facing a shortage of staff due to factors such as an aging population, growing competition, job insecurity, and low wages.

Solution: The implementation of IoT technology can alleviate this problem by enabling unskilled workers to learn at a quicker pace using advanced job training tools like virtual reality and augmented reality.

3. Multi-national supply chain

Logistics is very complex in the F&B industry since the supply chain caters to a multi-national market. This makes planning, tracking, and monitoring of supply chains very difficult and costly.

Solution: With IoT technology, supply route planning, inventory monitoring, and the coordination of storage and shipping across the supply chain can become more manageable, giving managers more time to make better decisions.

Key takeaway

The Internet of Things is undoubtedly essential for industrial development across all sectors, not only in the F&B industry. This is particularly true today, with a rapidly growing global population, industries becoming more competitive, and sustainability becoming a greater concern.